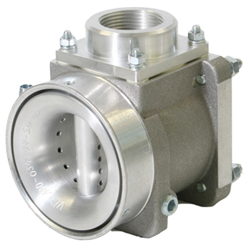

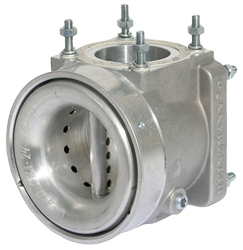

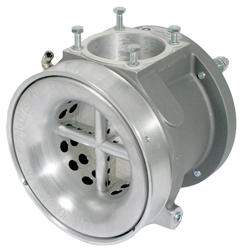

The KRONOS 20 is an electronically controlled mixture control system for adjusting speed-dependent and load-dependent lambda values in order to achieve ideal engine behaviour under all operating conditions. In the various closed loop versions, engine power, lambda or NOx sensors can be used as feedback signals to automatically correct fluctuations in gas quality and engine load. The main application areas are natural and biogas engines, which are supplied by a zero pressure controller.

For system configuration please provide application specific information: Order Information.