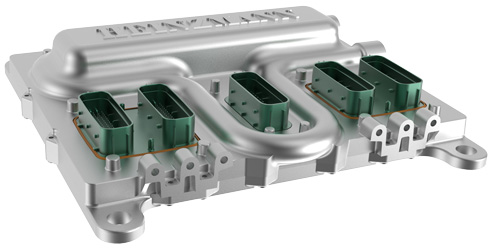

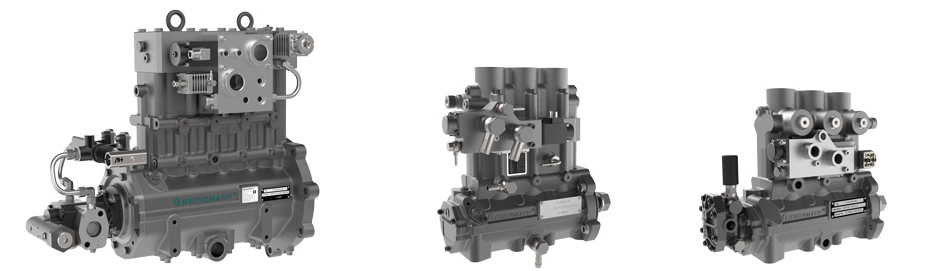

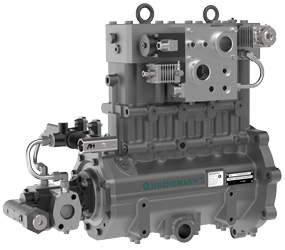

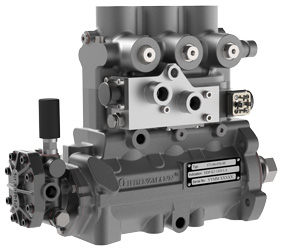

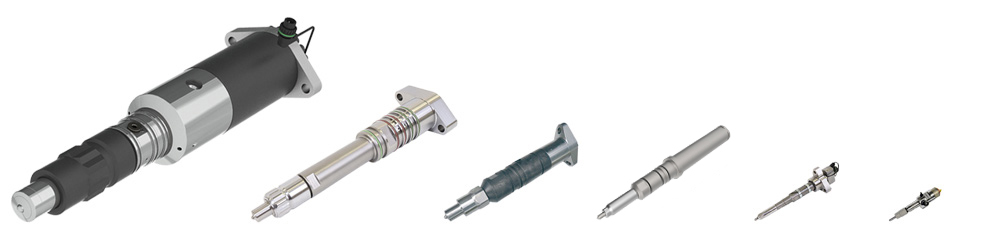

ODYSSEUS Common Rail Systems include all components for injection and for generating pressure, thereby guaranteeing optimum connectivity and compatibility. Together with the DARDANOS solenoid valve control units, the very precise hydro-mechanical components represent a holistic solution for state-of-the-art common rail injection technology. The ODYSSEUS range covers engine ratings from 150 to 10,000 kW and more. The different variants of the system are not only suitable for different engine sizes, but also different applications and fuel grades. In order to be able to guarantee the highest quality standards, all CR components are developed and >> manufactured by HEINZMANN itself.

For system configuration please provide application specific information: Order Information.

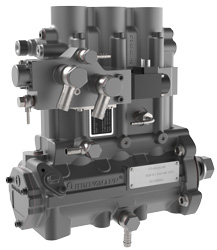

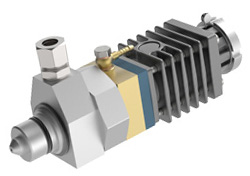

Pressure-limiting valves for protecting common rail systems against excess pressure; with fast-switching action for rapidly reducing the pressure.

Pressure-limiting valves for protecting common rail systems against excess pressure; with fast-switching action for rapidly reducing the pressure.