March 2018

Complying with prescribed exhaust gas limits affects almost all the areas in which internal combustion engines are used. Different approaches are needed for lean-burn engines and rich-burn engines. Versatile control systems from HEINZMANN provide sustainable solutions to these problems.

Building on its modular XIOS system, HEINZMANN offers optimised AdBlue injection to reduce pollution from lean-burn engines, and the E-LES LC system for lambda control. Both control solutions will be presented from April 23 – 27 at Hannover Messe: Stand K42/2, Hall 27.

The XIOS controller optimises AdBlue injection to reduce pollution

HEINZMANN developed its modular XIOS hardware platform to handle various application-specific control tasks in special-purpose vehicles, rolling stock, construction machines, ships and stationary installations.

The scalable basic model offers numerous inputs and outputs alongside its high-performance computing core, and can also be expanded with up to eleven pluggable I/O modules. The bandwidth of the various I/O modules covers everything from inputs for temperature sensors to 4Q control of actuators. If this is not enough for more complex tasks, you can also connect a number of controllers in master-slave mode, thus providing even more flexibility in expanding the available number of inputs and outputs. As alternatives to HEINZMANN’s existing software applications, users can develop their own functions and configurations based on CODESYS or MATLAB®/Simulink® to carry out control and monitoring tasks as needed and required by their specific applications. As communication interfaces, the controller offers 2 x Ethernet, 2 x CAN, USB, RS-232 and RS-485.

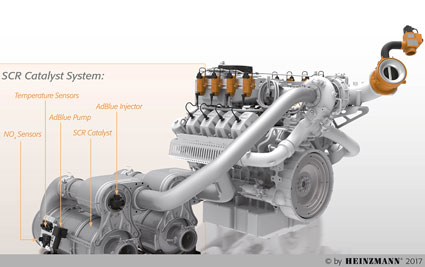

On the basis of its XIOS platform, HEINZMANN has developed an SCR control system that helps to comply with the increasingly stringent exhaust limits for NOx in lean-burn gas engines and diesel engines. Selective Catalytic Reduction (SCR) of nitrogen oxides in the exhaust gas by injecting urea in the form of AdBlue is at present state of the art. The XIOS controller ensures optimum dosage of the urea solution at all operating points. This application was specifically developed for use in special-purpose vehicles, rolling stock, ships and stationary industrial engines. The implementation paid particular attention to both minimising initial investment and reducing ongoing operating costs.

The control unit can optionally control and monitor one or two SCR systems. This involves recording and evaluating data received via CAN bus from up to four NOx sensors and four exhaust gas temperature sensors, plus other engine data such as boost and exhaust gas pressure, temperature, oil pressure, speed and so on. If necessary, the results can be used to simultaneously control one or two AdBlue injection systems. Comprehensive monitoring functions in the control system monitor the engine and the catalytic converter to prevent damage. A next step is to integrate an air-fuel-ratio control system for gas engines into the SCR control system in order to selectively regulate the engine’s raw emissions, using the existing NOx sensors to approach the desired values as closely as possible. At the same time the XIOS system’s integrated data logger records all the relevant measurements. A tank management system also monitors the tank level and the temperature of the AdBlue to ensure reliable exhaust purification all the time the engine is running.

E-LES LC - Gas control valve with integrated lambda 1 control

In order to fulfil the market’s increased demands regarding installation space, cost and emissions, the effective control strategy for industrial gas engines with stoichiometric combustion used for the proven KRONOS 20 control unit has also been integrated into the E-LES LC gas control valve. From now on, all the sensors needed for lambda control will be read directly by the control unit of the E-LES LC, thus freeing up the switch cabinet space that was previously occupied by the necessary control unit.

For its preliminary adjustment, the control mechanism uses physical calculations, taking into account not only engine-specific data, but also the gas composition and a variety of sensor measurements. The software regulates the voltage of the lambda probe, thus ensuring the long-term stable engine operation within the lambda window for which the KRONOS 20 system has long been known.

The system owes its ability to rapidly and precisely regulate the composition of the mixture, and thus the exhaust emissions, to the unique valve geometry of the E-LES LC. This valve is available in different sizes and possesses a number of triangular surfaces contained within a cylinder, which are released as appropriate by an axially guided piston. The cross-sections of these openings are optimized for the various engine sizes in such a way that the gas flow is precisely adapted for the appropriate load range while still being able to respond promptly to changed flow requirements. When combined with HEINZMANN’s Venturi gas mixers, this system provides for optimal mixture preparation and reliable exhaust aftertreatment in power ranges from 5 to 1750 kW, making it the ideal solution for any application.

The compact XIOS controller is the platform of an SCR control system for lean-burn gas and diesel engines

The compact XIOS controller is the platform of an SCR control system for lean-burn gas and diesel engines The modular XIOS controller is suitable for the control and monitoring of the exhaust aftertreatment of combustion engines in stationary and mobile use

The modular XIOS controller is suitable for the control and monitoring of the exhaust aftertreatment of combustion engines in stationary and mobile use  With its integrated lambda 1 control, the gas control valve E-LES 50 LC is predestined for its application in rich-burn engines

With its integrated lambda 1 control, the gas control valve E-LES 50 LC is predestined for its application in rich-burn engines

Contact and press requests: This email address is being protected from spambots. You need JavaScript enabled to view it.